- Contributions by industrial experts with engineers in mind

- Focused on specialty-chemical material applications and selection

Knowledge Center

Designing the proper thermal management system into your high powered electronics / Q&A

Because power input determines heat output, high-power electronics of any type, such as those used in semiconductors and electric vehicles, require effective thermal management. If heat isn’t dissipated, electronics won’t meet specifications or can fail altogether. This Q&A from Gluespec discusses these issues and offers solutions >

Find the right chemistry to protect your printed circuit board components

To create a long-lasting and reliable product, you need to ensure the PCBs can stand up to whatever conditions they will be used in, whether that means high humidity, salt fog, temperature extremes, electrical interference, chemicals or immersion in water. How you protect your PCB can determine the long-term performance of your end product. This article lists the methodologies and chemistries used for properly protecting printed circuit boards.

In Depth Questions and Answers on UV/Light Cure Adhesives

For design engineers who are considering implementing UV light cure adhesives in their new product development assembly, this Q&A from Gluespec® provides answers to frequently asked questions (FAQs).

Silicones in LED Lighting | Gluespec

Discover how silicones can play a wide variety of roles in the manufacturing of LED light equipment...

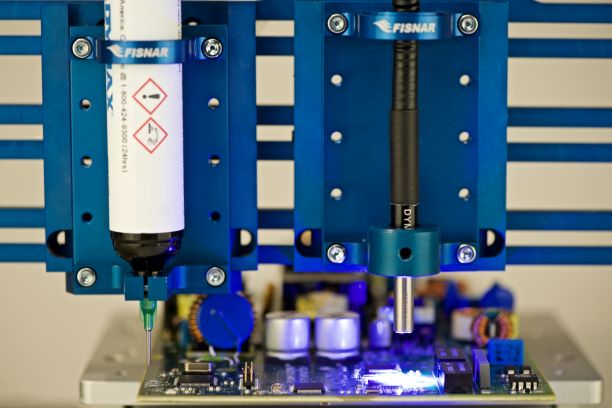

Accelerate Your Electronics Production with Dymax Speedmask® E-MAX 906-B Revision A

Perhaps the most notable advantage of using a UV-cured acrylated urethane as the mask in an electronics assembly process is that it is fast enough to speed up your manufacturing operations on the whole. Thus it allows you to create an automated assembly line without long racking times...read more