- Contributions by industrial experts with engineers in mind

- Focused on specialty-chemical material applications and selection

Knowledge Center

AI Data Center Electronics: Thermal Management and EMI Shielding Buyer's Guide

Listen to This Article

AI data centers have greater thermal management and EMI shielding requirements than traditional data centers. That’s because artificial intelligence (AI) uses servers with high-performance electronics to handle heavy workloads such as large data sets and complex algorithms. AI data centers also have higher hardware densities. They typically house more servers, and these resources are packed together to maximize the available rack space and minimize data transmission distances.

For engineers who design AI data center electronics, Gluespec is the place to find thermal management materials that can handle the higher heat associated with AI workloads and hardware densities. Gluespec is also where design engineers can find shielding against radio frequency interference (RFI) and electromagnetic interference (EMI): electronic noise or crosstalk that is generally more prevalent when electronic devices and systems are close by.

The materials and manufacturers in Gluespec’s database are not limited to specific suppliers, and data is quality-checked and updated as needed whenever new data sheets or product specifications are released. In this Buyer’s Guide, you’ll learn what you need to know about searching for and selecting thermal management, RFI, and EMI shielding for AI data center electronics. First, we’ll cover some key concepts and their relationship with product selection.

Table of Contents

Thermally Conductive Silicones

Bond Line Thickness, Wet-Out, and Thermal Resistance

Types of Thermal Management Materials

Thermal Phase Change Materials

Electrically Conductive Silicones

Types of EMI Shielding Materials

Finding Thermal Management and EMI Shielding for AI Data Center Electronics

AI data center operators need to optimize thermal management. Image Credit: C&C Wavetech

Thermal Management Challenges

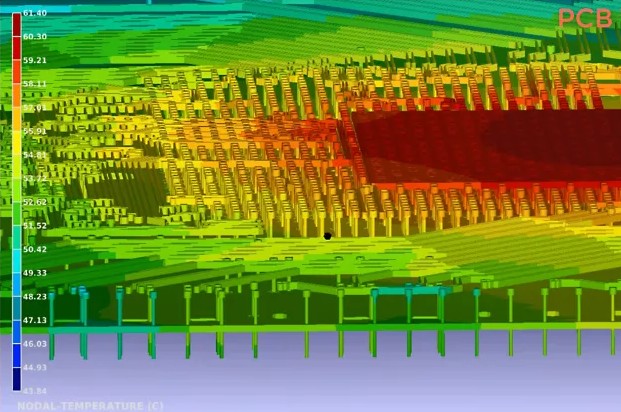

Heat is the enemy of electronics, and thermal management is about controlling the temperature of electronic devices and systems to ensure their reliability, performance and safety. Heat is related to power density, and AI’s higher power densities produce more heat. For example, AI hardware such as NVIDIA A100 graphics processing units (GPUs) can consume 400 – 700 W per card, with racks reaching 40-50+ kW. By contrast, traditional data centers reach 5-10 kW per rack.

AI workloads are greater, but they’re also more intense and draw power in bursts. This results in greater thermal load variability, an additional design challenge. Materials expand when heated and contract when cooled, but different materials have different coefficients of thermal expansion (CTE), a property that describes how much a material’s size changes with temperature. These temperature-related changes can cause stress and strain, leading to potential issues like cracking, deformation, or warpage in electronic assemblies.

Thermal mapping of heat and mechanical stress in ICs. Image Credit: Ansys

Thermally Conductive Silicones

Silicones are typically the chemistry of choice for thermal management challenges. These synthetic polymers withstand higher temperatures than organic materials, and silicones maintain their mechanical properties when thermal loads change. Importantly, silicones are also soft, flexible and stress-relieving. Epoxies are stronger, but they’re susceptible to cracking when electronic components expand and contract at different rates.

Normally, silicone is thermally insulating. However, the silicones that are used with AI data center electronics are thermally conductive instead. They contain specialized fillers that impart thermal conductivity (TC), a measure of the ability to move heat. Typically, TC is expressed expressed in watts per meter Kelvin (W/mK).

Bond Line Thickness, Wet-Out, and Thermal Resistance

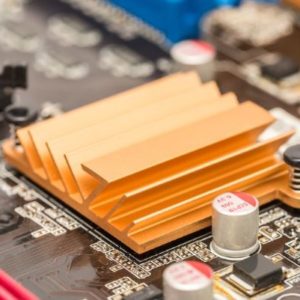

Thermally conductive silicones have TC values that are higher than the air that would otherwise fill these gaps. TC is about moving heat away from sensitive electronics to an aluminum-clad printed circuit board (PCB) or metal heat sink. But designers also need to consider bond line thickness and substrate wetting. Thinner bond lines mean there’s less distance for heat to travel, and a material that readily wets-out a substrate can usually be applied in a thinner layer. In turn, an engineer may be able to specify a product with a lower TC.

There are additional considerations as well. Thermal resistance is a measure of the opposition to the flow of heat. It’s the reciprocal of TC and is typically measured in Kelvin per watt (K/W). In PCB circuit design, thermal resistance is used to measure a package’s heat dissipation and to avoid overheating. When comparing a product with a lower TC to one with a higher TC, the product with a lower TC could be preferable if its thermal resistance is lower and the material has better wet-out.

Types of Thermal Management Materials

At the chip and board levels, electronic designers can specify the following types of thermal management materials for AI data center electronics.

- Thermal gap fillers

- Thermal gap pads

- Thermal gels

- Thermal phase change materials

- Thermal greases and compounds

The following sections explain.

Thermal Gap Fillers

Thermal gap fillers flow and conform to intricate PCB topographies, including multi-level surfaces. Because they are dispensed and wet-out in a liquid state, these products put minimal stress on electronic components during assembly. Liquid gap fillers require curing, a chemical process that transforms a product into a solid and imparts its final properties.

These are some of the thermal gap fillers you’ll find on Gluespec.

|

Gap Filler 2000 from Henkel is a two-part silicone liquid with a TC of 2 W/mK. It cures at room temperature but also supports accelerated heat curing. |

|

TIA222G from Momentive is a two-part silicone liquid with a TC of 2.20 W/mK. It cures at room temperature. |

|

Dowsil TC-4551 CV from Dow is a two-part silicone liquid with a TC of 5 W/mK. It cures at room temperature but also supports accelerated heat curing. |

Here are some additional resources about thermal gap fillers.

A Guide to Thermal Gap Fillers

How to Identify Quality Thermal Gap Fillers in Four Steps

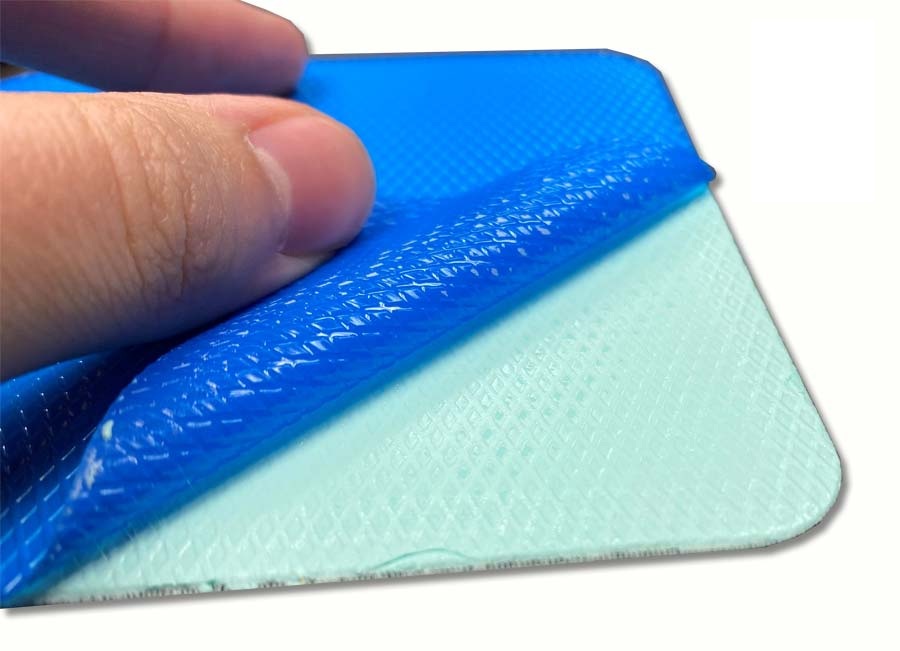

Thermal Gap Pads

Thermal gap pads are soft, compressible, and easy to reposition and remove. They’re available in a range of thicknesses and can be die-cut into simple squares and rectangles or complex shapes that can accommodate intricate features. Thermal gap pads do not require curing, and robotic equipment can be used for high-volume assembly.

These are some of the thermal gap pads you’ll find on Gluespec.

|

TP-1560 from Resin Lab is a silicone gap pad that resists temperatures up to 302°F. It has a TC of 1.10 W/mK. |

|

Bergquist TGP 3500ULM from Henkel is a silicone gap pad that resists temperatures up to 392°F. It has a TC of 3.50 W/mK. |

|

P-THERM PS-2505 from Polymer Science, Inc. is a silicone gap pad that resists temperatures up to 392°F. It has a TC of 5 W/mK. |

Here are some additional resources about thermal gap pads.

Protecting Equipment with a High-Performing Gap Filler Pad

The Best Thermal Gap Pad for Your Design

The Key Role of Thermal Gap Pads in Network Switch Cooling

Thermal Gels

Thermal gels are very soft and compress readily under low force. Because they have a low modulus, they won’t put significant pressure on AI server chips. Among their advantages, gels flow readily and fill small surface discontinuities. However, they can be challenging to apply evenly and require curing. Some gels may entrain air bubbles during production or become powdery with age.

These are some of the thermal gels you’ll find on Gluespec.

|

KE-1869 from Shinetsu is a one-part silicone thermal gel that resists temperatures up to 302°F. It has a TC of 1.10 W/mK. |

|

EP-2490 from Nusil is a two-part silicone thermal gel that resists temperatures up to 482°F. It has a TC of 1.49 W/mK. |

|

SE 4445 CV from Dow is a two-part silicone gel that resists temperature us to 392°F. It has a TC of 1.25 W/mK. |

Here are some additional resources about thermal gels.

How to Prevent Thermal Gel Powderization

Thermal Phase Change Materials

Thermal phase change materials (PCMs) are thin, waxy films that are used between a chip and a cooling plate. The are commonly available in sheet form and can be die-cut into specific shapes. When the chip heats up, the wax-like material melts and flows into gaps. Cooling causes the material to return to its original state. Some PCMs have relatively low TC values, and volume changes during phase transitions are possible.

These are some of the thermal phase change materials you’ll find on Gluespec.

|

TM550 from Electrolube contains a solvent to ensure complete wet-out. It has a TC of 3.50 W/mK. |

|

Bergquist Hi Flow THF 1000F-AC from Henkel has a TC of 3.50 W/mK. It’s used between computer processors and heat sinks. |

|

PCS-PL-30 from Shinetsu has a thermal conductivity of 1.79 W/mK. It’s used with LED and power modules. |

Here are some additional resources about thermal phase change materials.

Understanding Phase Change Materials

Thermal Management of Electronic Equipment Using Phase Change Materials (PCMs)

Enhancing Electronics with Advanced Composite Phase Change Materials

Thermal Greases and Compounds

Thermally conductive greases and compounds do not require curing. They can be messy, but server manufacturers typically apply them with an automated process like screen printing. Among their advantages, these products can be applied in very thin layers. Newer greases can be formulated to resist pump-out, the loss of the liquid carrier at the thermal interface.

These are some of the thermal greases and compounds you’ll find on Gluespec.

|

Silso Cool 18498 from CHT resists temperatures up to 356°F and has a TC of 1.58 W/mK. |

|

X-23-7921-5 from Shinetsu is used with semiconductor devices and has a TC of 6 W/mK. |

|

TC-5021 from Dow resists temperatures up to 392°F and has a TC of 3.30 W/mK. |

Here are some additional resources about thermal greases and compounds.

What are the Disadvantages of Thermal Grease?

Reliability Testing of Thermal Greases

Unlocking the Secrets of Thermal Grease Using Machine Learning

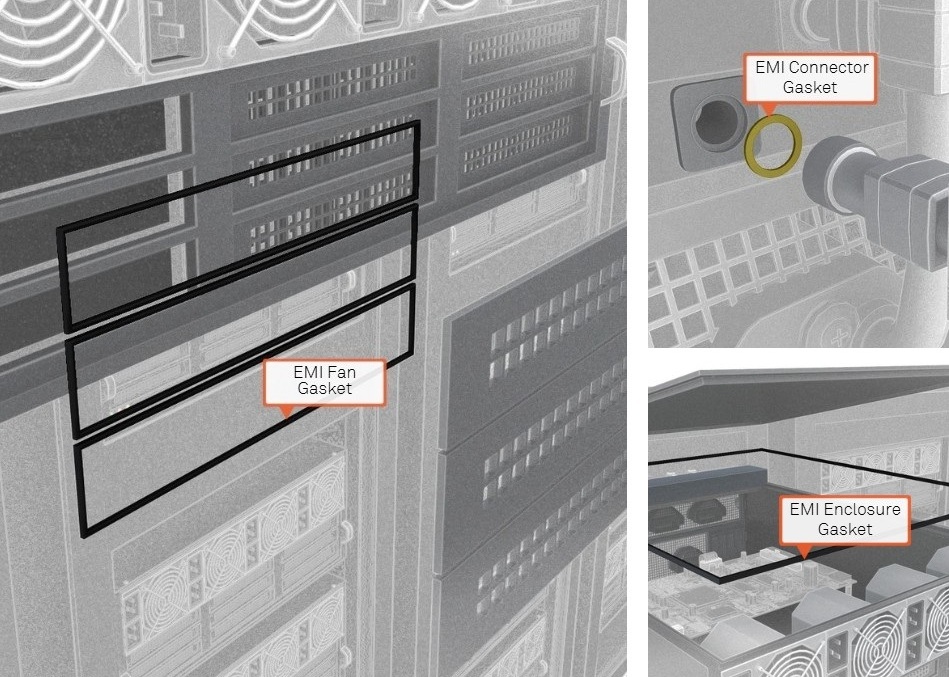

AI data center electronics use several types of EMI gaskets. Image Credit: Elasto Proxy

EMI Shielding Challenges

EMI generation is a challenge in AI data center electronics because GPUs operate at high clock frequencies and use high-speed memory buses. In addition, densely packed GPU servers create near-field EMI coupling, which requires reliable isolation and shielding. EMI adhesives are applied at the chip and PCB level, but EMI gaskets and shielded enclosures are also used. Often, these enclosures are made of metal and/or use EMI coatings.

Electrically Conductive Silicones

Silicones have a combination of electrical, mechanical, thermal, and chemical properties that are well-suited for demanding electronic environments. Normally, silicones are electrically insulating. However, adding metal or metal-coated fillers to a silicone base creates an electrically conductive compound instead. Materials with higher electrical conductivity reflect more electromagnetic radiation, which prevents interference.

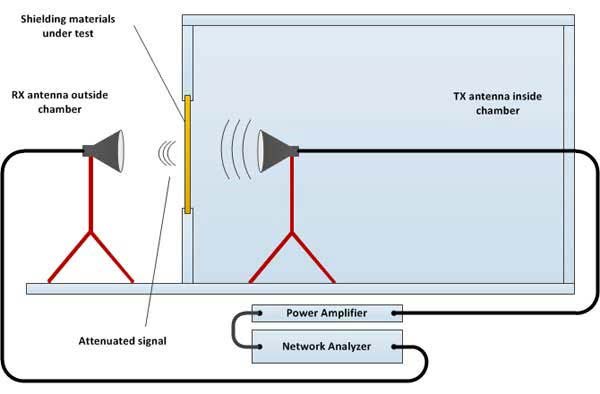

Testing a material for shielding effectiveness. Image Credit: Absolute EMC

Shielding Effectiveness

EMI shielding effectiveness is measured by attenuation, which quantifies the reduction in signal strength after passing through a shield. Typically, decibels (dB) are the unit of measure. Sometimes, however, volume resistivity (VR) is listed instead. VR is an indirect measurement of EMI shielding effectiveness that indicates a material's resistance to leakage current. The unit of measure is ohms per centimeter (oh-cm).

Types of EMI Shielding Materials

AI data center electronics use two main types of silicone-based materials for EMI shielding: adhesives and gaskets. EMI adhesives are electrically conductive, and some products also provide thermal conductivity. EMI gaskets can be made of solid elastomers or have a fabric-over-foam construction. Choices also include form-in-place (FIP) gaskets that are dispensed as a liquid and then cured in place.

EMI Adhesives

EMI adhesives combine electrical conductivity with adhesive bonding. In AI data center electronics, they’re often used to bond EMI shields over high-frequency microprocessors, RF chips, and wireless modules. Often, EMI shields are metal enclosures or coatings that provide a barrier. EMI adhesives are also used to bond heat sinks, attach electrically conductive foils or fabrics, and attach EMI gaskets to PCB surfaces or enclosures that require electrical conductivity.

These are some of the EMI adhesives you’ll find on Gluespec.

|

CHO-Bond 1077 from Parker Chomerics is a one-part silicone adhesive that’s filled with nickel-plated aluminum particles. |

|

Loctite Ablestik ICP 811SP from Henkel combines reliable adhesion with fast curing for high-volume processing. |

|

Dowsil EC-6601 from Dow is used for PCB grounding and has a CE of 2.7 ohm-cm. |

Here are some additional resources about EMI adhesives.

Adhesives and Coatings Used for EMI/RFI Shielding

EMI Shielding: Protecting Electronic Devices in a Noisy World

Conductive Adhesives 101: A Beginner’s Guide

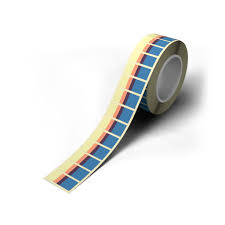

EMI Gaskets

EMI gaskets that are made of electrically conductive silicones combine reliable shielding with environmental sealing and high-temperature insulation. Fabric-over-foam gaskets have a conductive fabric or foil with a foam core. They are often used in applications where low compression force is required. Silicone foams that are impregnated or coated with conductive materials are also used. FIP gaskets are used for high volumes of AI data center electronics with complex geometries.

These are some of the EMI gasket materials you’ll find on Gluespec.

|

SSP502-40V0 is a 40-durometer, nickel-graphite EMI silicone with UL 94 V0 flame resistance. It has a VR of .05 ohm-cm. |

|

|

9111S-100 from 3M is an electrically conductive double-sided tape that provides EMI shielding and grounding.

|

|

CHO-Bond 1038 from Parker Chomerics is filled with silver-plated copper and has a VR of .010 ohm-cm. |

|

Nusil R-2631 is a two-part methyl silicone polymer that cures with heat to produce FIP gaskets. |

Here are some additional resources about EMI gaskets.

How Do EMI Gaskets Work to Protect Your Equipment?

Conductive Elastomer Engineering Handbook

MIL-DTL-83528 Type A, B, C, D, and K Materials for EMI Gaskets

Finding Thermal Management and EMI Shielding for AI Data Center Electronics

Gluespec’s comprehensive and quality-tested database of 35,000 adhesives includes the thermal management materials that design engineers need. The materials and manufacturers in our database are not limited to specific suppliers, and data is quality-checked and updated as needed whenever new data sheets or product specifications are released.

If you need deep data about thermal management materials, you’ll find what you’re looking for in our proprietary database. Along with technical data and key specifications, you’ll find best practices and comparable materials. Design engineers can also view test method information on dozens of material properties and data points.

Finally, Gluespec’s Advanced Search provides the tools you need to conduct deep filtering among all material properties. The result is a customized grid that contains materials and data points that are specific to your project. Save custom grids for quick access and share them, along with this Thermal Management Buyer’s Guide, with your colleagues.