- Contributions by industrial experts with engineers in mind

- Focused on specialty-chemical material applications and selection

Knowledge Center

Conformal Coatings Guide

Listen to This Article

Conformal coatings are thin, polymeric films that are applied to printed circuit boards (PCBs) to protect the boards and their components from the environment. They can be applied manually with brushes, aerosols, and spray guns, or with dip coating and selective coating machines. Typically, conformal coatings are applied at thicknesses between 25 and 250 µm.

This guide explains what design engineers need to know about selecting conformal coatings, a category of products you’ll find on Gluespec.

Gluespec's comprehensive and quality-tested database of 35,000 adhesive materials includes the conformal coatings that design engineers need. Along with technical data and key specifications, you’ll find best practices and comparable materials. You can also view test method information on dozens of material properties and data points.

Table of Contents

Introduction

Types of Conformal Coatings

- Acrylic

- Polyurethane

- Silicone

- Epoxy

- Synthetic Rubber

- Solvent-Based

- Solvent-Free

- VOC-Free

- Water-based

- UV/Visible

- UL

Introduction

As their name suggests, conformal coatings are designed to conform to the shape of the PCB and its electronic components. They exhibit good adhesion and form strong bonds from the adsorption of coating molecules on the substrate and the resulting attractive forces. By protecting solder joints, component leads, exposed traces, and other metalized areas, conformal coatings help to extend the life of electronics. It’s important to note, however, that most materials are water-resistant rather than waterproof.

Types of Protection

New PCBs and printed circuit board assemblies (PCBA) may perform well at first, but their performance can deteriorate rapidly because of the operating environment. Moisture, salt spray, dust, chemicals, and extreme temperatures can cause or contribute to problems such as corrosion, electrical failures, and even the growth of mold. The environmental protection that conformal coatings provide isn’t their only benefit, however. These materials can also support the use of higher voltage gradients and closer spacing for high-power electronics and device miniaturization.

Selection Considerations

When selecting conformal coatings, design engineers need to consider both the chemistry and the curing system. Chemistries include acrylic, polyurethane, silicone, epoxy, and synthetic rubber. Curing systems include moisture, evaporation, heat, light, and dual curing mechanisms. Substrate material, electrical properties, hardness, and flexibility are key product specifications. Both solvent-based and solvent-free products are available. Design engineers can also choose conformal coatings that are free of volatile organic compounds (VOCs), are water-based, or meet Underwriters Laboratory (UL) standards.

Types of Conformal Coatings

Gluespec divides conformal coatings into various categories and makes it easy to search for them online. Within each category, you can search for products based on technical specifications for curing, bond strength, material resistance, conductivity, and other properties.

The following sections describe each category of potting and encapsulating materials in detail. You’ll also find links to technical resources with additional information, either in the Gluespec Knowledge Center or from other trusted resources.

Acrylic Conformal Coatings

Acrylic conformal coatings provide broad but basic protection against environmental contaminants. They have excellent dielectric strength, but only fair moisture and abrasion resistance. In addition, they lack strong chemical resistance. Among their advantages, acrylic conformal coatings are easy to remove with a variety of solvents. This makes them suitable for rework and field repairs. Yet it also means that acrylic conformal coatings do not provide protection against solvents and solvent vapors. Acrylic conformal coatings are only best-in-class for dielectric strength, but these materials are cost-effective.

Applications

Applications for acrylic conformal coatings include:

- Lower-cost consumer products

- Repairable electronics

- Rigid and flexible PCB substrates

Products

These are some of the acrylic conformal coatings you'll find on Gluespec.

|

HumiSeal 1B73 is an acrylic conformal coating with a high tack resistance at elevated temperatures. It has excellent electrical properties and flexibility. |

|

DYMAX Multi-Cure 984-LVUF is a 100% solids product that cures with UV light and is in full compliance with RoHS 2015/863/EU. |

|

ELANTAS PDG CONAP CE-1170 cures at room temperature and maintains excellent adhesion to phenolic and epoxy-glass laminates, even in adverse environmental conditions. |

|

Techspray 2108 is a fast curing, non-ozone depleting aerosol that's used to accelerate board production. It fluoresces under UV light to aid inspection. |

Tech Specs

Here are some of the technical specifications for acrylic conformal coatings like HumiSeal 1B73.

|

Type |

Spec |

Definition |

|

Cure |

Cure Time (min)

|

The length of time needed for a conformal coating to fully cure, acquiring its end-use properties. |

|

Conductivity |

Dissipation Factor |

A measure of the loss rate of electrical energy in a dissipative system. |

|

Hardness |

Flexibility |

The ability of a conformal coating to bend easily or without breaking |

Resources

Here are some additional resources about acrylic conformal coatings.

- Finding the Right Chemistry to Protect Your PCB Components

- Acrylic Conformal Coatings

- Electrical Insulation of Conformally Coated Printed Circuit Boards

Polyurethane Conformal Coatings

Polyurethane conformal coatings provide excellent moisture and chemical resistance. They are also very resistant to abrasion, mechanical wear, and solvents. This makes them difficult to remove and best suited for electronics that are not intended to be repaired. Typically, full removal requires specialized solvents, a long soak time, and agitation with either a brush or an ultrasonic bath. Single-component polyurethane conformal coatings are easy to apply but take longer to cure than two-part systems. Polyurethane conformal coatings require a lengthy post-cure time, and these materials can yellow with age.

Applications

Applications for polyurethane conformal coatings include:

- Motors

- Generators

- Transformers

Products

These are some of the polyurethane conformal coatings you'll find on Gluespec.

|

1A27 from HumiSeal is an oxygen-curing, single-component product with excellent electrical properties. It's also available in aerosol cans. |

|

Conathane CE-1164 from ELANTAS maintains excellent adhesion to phenolic and epoxy-glass laminates even in adverse environmental conditions. |

|

UR Urethane Conformal Coating 2104 from Techspray is a durable and provides protection against chemicals, moisture, and abrasion. |

|

Loctite Stycast UV 7993 from Henkel provides rugged protection from moisture and harsh chemicals. Applications include radar and guidance systems. |

Tech Specs

Here are some of the technical specifications for polyurethane conformal coatings like Dymax® Multi-Cure 984-LVUF.

|

Type |

Spec |

Definition |

|

Cure |

Cure Temperature (°F)

|

The required temperature for a conformal coating to cure |

|

Bond Strength |

Tensile Strength (psi)

|

The resistance of the material to breaking under tension. |

|

Conductivity |

Dielectric Strength (V/mil) |

The electrical strength of an electrically insulating material. |

Resources

Here are some additional resources about polyurethane conformal coatings.

- Conformal Coatings

- Polyurethane Conformal Coatings for Electronics

- Polyurethane Conformal Coatings: When to Consider an Alternative

Silicone Conformal Coatings

Silicone conformal coatings provide reliable environmental protection across a wide temperature range. They aren’t especially abrasion resistant, but their rubbery nature enables them to withstand vibrational stresses. Typically, silicone conformal coatings are used in high heat and high humidity environments. They also offer good resistance against chemicals and salt spray. Because they remain flexible, silicone conformal coatings are a good choice when there are mismatches in the coefficients of thermal expansion (CTE) between PCB and component materials. Silicones can’t match epoxies in bond strength, however.

Applications

Applications for silicone conformal coatings include:

- LED lighting

- Automotive electronics

- Outdoor signage

Products

These are some of the silicone conformal coatings you'll find on Gluespec.

|

Dowsil 1-2577 Conformal Coating from Dow is a one-part, medium-viscosity product that is solvent-borne and translucent in color. After curing, it's abrasion-resistant. |

|

Fine-L-Kote HT 2106 from Techspray is a one-part product that withstands extreme temperatures and has excellent adhesion properties. It resists moisture and fungus. |

|

1C51 Silicone Conformal Coating from HumiSeal is a VOC-free product for fast thermal curing. It's low viscosity and long pot life make it ideal for dipping and spraying. |

|

CV-1152 from Nusil is an RTV silicone conformal coating with controlled volatility. It's suitable for rigid and flexible PCBs, connectors, and switches. |

Tech Specs

Here are some of the technical specifications for silicone conformal coatings like Dow 1-2577 RTV Coating.

|

Type |

Spec |

Definition |

|

Cure |

Viscosity (cPs)

|

Viscosity is a measure of a fluid’s resistance to flow |

|

Conductivity |

Dielectric Constant |

The ratio of an insulator’s capacitance to that of dry air. A dielectric constant of 10 means the insulator will absorb 10x more electrical energy than air. |

|

Other Properties |

Specific Gravity |

The ratio of the density of a substance to the density of some substance (such as pure water) taken as a standard when both densities are obtained by weighing in air. |

Resources

Here are some additional resources about silicone conformal coatings.

- Silicones in LED Lighting

- Conformal Silicone Coatings in Automotive Electronics

- How to Evaluate the Best Silicone Conformal Coating

Epoxy Conformal Coatings

Epoxy conformal coatings provide strong resistance to humidity, chemicals, and abrasion. They have greater adhesion strength than silicones or polyurethanes, but are generally hard and brittle. Typically, epoxy conformal coatings are difficult to remove. Because they are less flexible, epoxies are also susceptible to cracking. Epoxies can be formulated with a wide range of properties, however, including thermal and electrical conductivity. Unlike other types of materials, epoxies usually aren’t permeable. Their high-temperature resistance and thermal stability isn’t as great as silicone, but epoxies offer greater bond strength and adhere to a variety of substrates.

Applications

Applications for epoxy conformal coatings include:

- Power supplies

- Marine electronics

- Military electronics

Products

These are some of the epoxy conformal coatings you'll find on Gluespec.

|

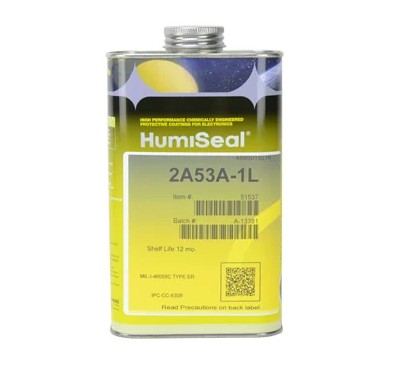

2A53 from HumiSeal is a two-part, heat-cured, liquid epoxy that provides exceptional resistance to abrasion, solvents, and chemicals. |

|

Axis UV-921 from Resin Designs is a one-part, liquid gel that cures with UV or visible light. It has a low viscosity and is a flexible adhesives with autoclave resistance. |

|

EP1320 from Resinlab is a one-part, heat-cured product that can also be used a small-mass potting compound, structural adhesive, or insulating polymer system. |

|

Multi-Cure 9452-FC from Dymax is a thin, one-part, 100% solids product that cures with light. It supports film coating, flow coating, and similar dispensing methods. |

Tech Specs

Here are some of the technical specifications for epoxy conformal coatings like Parker LORD Cooltherm EP-343.

|

Type |

Spec |

Definition |

|

Cure |

Work/Pot Time (min)

|

Pot life is the length of time in which multiple part coatings or paints can be applied to a surface |

|

Conductivity |

Insulation Resistance |

Insulation resistance is the total resistance between any two points separated by electrical insulation. |

|

Other Properties |

Elastic Modulus |

Elastic modulus quantifies a material’s resistance to non-permanent, or elastic, deformation. |

Resources

Here are some additional resources about epoxy conformal coatings.

- Epoxy Conformal Coating: Benefits, Disadvantages & Uses

- Epoxy Conformal Coating Evaluation Guide

- Potting vs. Conformal Coating of PCB Assemblies

Synthetic Rubber Conformal Coatings

Compared to other available materials, synthetic rubber conformal coatings have better mechanical properties and withstand higher operating temperatures. They are extremely flexible, offer superior moisture protection, and help minimize dendritic growth (tin whiskers) in electronics. They also adhere to a variety of substrates, have high elongation, and have a low CTE for reduced stress on components. Synthetic rubber conformal coatings are solvent-based, however, which may raise environmental health and safety (EHS) concerns. For high throughput, they support fast drying by solvent evaporation.

Applications

Applications for synthetic rubber conformal coatings include:

- Fine-pitch technologies

- High-temperature applications

- Military and aerospace electronics

Products

These are some of the synthetic rubber conformal coatings you'll find on Gluespec.

|

1B51NSLU from HumiSeal is a fast-drying, one-part product that contains methylcyclohexane solvent, which is more environmentally-friendly than traditional solvents. |

|

Aromatic Free Low Temperature Coating (LTC) from Electrolube is a fast-drying and highly flexible product that is designed to protect high-performance elecronic circuits. |

Tech Specs

Here are some of the technical specifications for synthetic rubber conformal coatings like HumiSeal 1B51NSLU.

|

Type |

Spec |

Definition |

|

Cure |

Work/Pot Time (min)

|

Pot life is the length of time in which multiple part coatings can be applied to a surface |

|

Bond Strength |

Tensile strength (psi)

|

Tensile strength is the resistance of a material to breaking under tension. |

|

Conductivity |

Insulation Resistance |

Insulation resistance is the total resistance between any two points separated by electrical insulation. |

Resources

Here are some additional resources about synthetic rubber conformal coatings.

- What are Synthetic Rubber Conformal Coatings & Their Advantages?

- Conformal Coating and Thermal Shock Resistance

- Conformal Coating Selection

Solvent-Based Conformal Coatings

Solvent-based conformal coatings are thinned with solvents so that the polymeric based resin flows and dispenses properly. Typically, they also contain diluents. Compared to water-based products, solvent-based conformal coatings are better at resisting harsh environmental conditions. Solvent-based conformal coatings also have greater bond strength and are available in one-part systems for ease of application. High concentrations of solvent fumes are considered to be hazard, however, and spent solvents may be require specialized disposal. Most organic solvents are combustible and are often highly volatile (i.e., easily turn into a gas or vapor).

Applications

Applications for solvent-based conformal coatings include:

- Industrial electronics

- Military electronics

- Automotive electronics

Products

These are some of the solvent-based conformal coatings you'll find on Gluespec.

|

Dowsil 1-2577 Conformal Coating from Dow is a one-part liquid that is solvent-borne and cures at room temperature. It provides an abrasion resistant surface after curing. |

|

1B31LOC from HumiSeal is a one-part, solvent-based liquid that is fast-drying and complies with all current air quality regulations. |

|

Conap CE-1170 from Elantas is a one-part product that cures at room temperature. It's cured films maintain excellent adhesion to phenolic and epoxy-glass laminates. |

Tech Specs

Here are some of the technical specifications for solvent-based conformal coatings like Elantas Conap CE-1170.

|

Type |

Spec |

Definition |

|

Cure |

Work/Pot Time (min)

|

Pot life is the length of time in which multiple part coatings or paints can be applied to a surface |

|

Bond Strength |

General Bond Strength (psi)

|

The amount of adhesion between the bonded substrates |

|

Material Resistance |

Flame Resistance |

The ability of a material to resist the support and conveyance of fire between any two points separated by electrical insulation |

Resources

Here are some additional resources about solvent-based conformal coatings.

- Current and Future Trends in Conformal Coatings

- Conformal Coatings Protect Automotive Electronics

- Conformal Coating Fumes

Solvent-Free Conformal Coatings

Solvent-free conformal coatings do not contain common coating solvents, such as toluene and xylene, that are categorized as hazardous air pollutants. Therefore, these products can reduce or eliminate the EHS, disposal, and regulatory concerns that are associated with traditional solvent-based materials. Solvent-free conformal coatings also have low levels of outgassing and are available in various chemistries and cure systems. Because there are no solvents to evaporate, they require thinner layers and can sometimes be applied in a single pass.

Applications

Applications for solvent-free conformal coatings include:

- Unmanned aerial vehicles

- Satellite communications

- Cameras and optical systems

Products

These are some of the solvent-free conformal coatings you'll find on Gluespec.

|

Dowsil 3-1953 Conformal Coating from Dow is a solvent-less product for rigid and flexible PCBs. Use with lighting, indusrial, and automotive applications. |

|

1C49LV from HumiSeal can be cured at room temperature or at elevated temperatures. It fluoresces under UV light and both solvent-free and VOC-free. |

|

Multi-Cure 9-20557-LV from Dymax contains no reactive solvents and fully complies with RoHS directives 2015/863/EU. |

Tech Specs

Here are some of the technical specifications for solvent-free conformal coatings like Henkel Loctite Stycast UV 7993.

|

Type |

Spec |

Definition |

|

Material Resistance |

High Temperature Resistance (°F)

|

The highest temperature that a material can withstand without a significant reduction in properties |

|

Conductivity |

Volume Resistivity (ohms-cm) |

The ratio of electrical resistance through a cross-section divided by length through which current flows. |

|

Other Properties |

Flash Point (°F) |

The lowest temperature at which vapors above a combustible substance ignite in air when exposed to flame. |

Resources

Here are some additional resources about solvent-free conformal coatings.

- Silicone Conformal Coatings for Solventless Curing

- Solvent-Free Coatings: Can We Rely on Them?

- The Evolution of Conformal Coating?

VOC-Free Conformal Coatings

Volatile organic compounds (VOC) are found in some of the solvents and diluents that are used to disperse the polymeric resin in conformal coatings. A broad category of chemicals, VOCs are emitted as gases into the air and can adversely affect human health. Consequently, VOC-containing substances may require special handling, fume removal, and disposal. They may also be subject to government regulations. By replacing a VOC-containing thinner with one that is VOC-free, manufacturers can address these concerns and reduce facility-level VOC emissions.

Applications

Applications for VOC-free conformal coatings include:

- Consumer electronics

- Commercial electronics

- Medical devices

Products

These are some of the VOC-free conformal coatings you'll find on Gluespec.

|

PC40-UM from Henkel is a one-part, VOC-free product that is formulated to gel rapidly when exposed to UV light. It then cures with atmospheric moisture. |

|

UVA300 from HumiSeal is a one-part, non-flammable product. It has an acrylated polyurethane chemistry and fluoresces under UV light. |

|

2K300 from Electrolube is a two-part, high-performance, VOC-free product that is designed specifically for selective coating processes. |

Tech Specs

Here are some of the technical specifications for VOC-free conformal coatings like Elantas Conap CE-1170.

|

Type |

Spec |

Definition |

|

Cure |

Work/Pot Time (min)

|

Pot life is the length of time in which multiple part coatings or paints can be applied to a surface |

|

Bond Strength |

General Bond Strength (psi)

|

The amount of adhesion between the bonded substrates |

|

Material Resistance |

Flame Resistance |

The ability of a material to resist the support and conveyance of fire between any two points separated by electrical insulation |

Resources

Here are some additional resources about VOC-free conformal coatings.

- Technical Overview of Volatile Organic Compounds

- What is the Difference Between a Solvent and Diluent?

- Conformal Coatings: Non-VOC

Water-Based Conformal Coatings

Water-based conformal coatings use water to thin conformal coatings so that they flow and dispense properly. Note, however, that water-based conformal coatings are not necessarily solvent-free. Some products contain chemicals known as co-solvents, which are solvents in lower concentrations that help to evaporate water during drying. Yet even if they contain co-solvents, water-based conformal coatings help to address the EHS, disposal, and regulatory concerns surrounding VOCs. Compared to solvent-based products, however, water-based conformal coatings have less environmental resistance.

Applications

Applications for water-based conformal coatings include PCBA assembly in:

- Confined or poorly ventilated spaces

- Low humidity environments

- Indoor locations for repairs

Products

These are some of the water-based conformal coatings you'll find on Gluespec.

|

WBPS from Electrolube is one-part liquid that drys with air and is formulated to protect electronic circuits. It is milky white in color but is clear and transparent when cured. |

|

Wondermask PX Peelable Solder Mask 2222 from Techspray is a temporary, peelable product that is applied by hand and withstands fluxing and wave soldering. |

|

1H2O AR2 Acrylic Coating w/ S from HumiSeal is available in versions that are suitable for dip coating, spraying, selective spraying, or brushing. |

|

Conathane CE-1175 from Elantas is designed for designed for thin-film applications and developed to provide humidity resistance and hydrolytic stability. |

Tech Specs

Here are some of the technical specifications for water-based conformal coatings like Elantas Conathane CE-1175.

|

Type |

Spec |

Definition |

|

Cure |

Thixotropic

|

A thixotropic fluid is one that takes a fixed time to return to its equilibrium viscosity when subjected to abrupt changes in shear state. |

|

Material Resistance |

Flame Resistance |

The ability of a conformal coating to resist the support and conveyance of fire. |

|

Other Properties |

% Solids |

The percentage by weight of non-volatile matter in a conformal coating. |

Resources

Here are some additional resources about water-based conformal coatings.

- Water-Based Coatings Solvent-Based Coatings

- Waterborne Coatings: Methods, Benefits, and Applications

- Which PCB Coating Should I Use for My Boards?

UV/Visible Light Cure Conformal Coatings

UV/visible light cure conformal coatings cure with ultraviolet (UV) light or visible light. Irradiation at a specific wavelength and energy intensity is required, and some UV-cured products fluoresce to indicate the presence of light. To reach shadowed areas where UV light or visible light cannot penetrate, or light-based curing is otherwise incomplete, a secondary moisture cure may be used. UV/visible light cure conformal coatings come in a variety of chemistries and are typically solvent-based; however, newer solventless formulas are available. Compared to the thermal ovens used for heat-based curing, UV curing equipment uses less energy and has a smaller footprint.

Applications

Applications for UV/visible light cure conformal coatings include:

- Smartphones

- Medical devices

- 5G electronics

Products

These are some of the UV/visible light cure conformal coatings you'll find on Gluespec.

|

UV40 UV Curable Conformal Coating from HumiSeal is a one-part, acrylated polyurethane product with excellent chemical resistance and surface hardness. |

|

Multi-Cure 984-LVUF from Dynax is a one-part, 100% solid conformal coating that is formulated for rapid room-temperature curing when exposed to UV light. |

Tech Specs

Here are some of the technical specifications for UV/visible light conformal coatings like Resin Designs Axis UV-921.

|

Type |

Spec |

Definition |

|

Cure |

Fluorescent |

A fluorescent surface, substance, or color has a very bright appearance when light is directed onto it, as if it is actually shining itself. |

|

Conductivity |

Dissipation Factor |

A measure of loss-rate of energy of a mode of oscillation (mechanical, electrical, or electromechanical) in a dissipative system |

|

Hardness |

Flexibility |

The ability to bend easily or without breaking |

Resources

Here are some additional resources about UV/visible light cure conformal coatings.

- The Different Conformal Curing Techniques

- UV-Curing Technology Continues to Shed Light on Assembly Techniques

- On the Right Wavelength

UL Conformal Coatings

UL conformal coatings meet requirements from Underwriters Laboratories (UL), which develops safety standards for materials used with PCBs. There are many UL standards, but two are especially important for conformal coatings. UL-746E comprises a series of tests for dielectric strength and flame retardance. Unlike permanent and resist coatings, conformal coatings must pass both types of tests. UL 94 is used to measure the burn rate of a horizontal or vertical specimen of a specific thickness. There are five different UL 94 flame ratings that apply to conformal coatings: HB, V-2, V-1, V-0, and 5-V.

Applications

Applications for UL conformal coatings include:

- Avionics

- Appliances

- Automotive electronics

Products

These are some of the UL conformal coatings you'll find on Gluespec.

|

Dowsil 3-1953 Conformal Coating from Dow is a solvent-less elastomeric coating that meets UL 746E requirements. It is translucent in color and ozone-resistant. |

|

1A27 from HumiSeal is an oxygen-curing, one-part, polyurethane coating that has excellent electrical properties and provides a heavy build. |

|

Fine-L-Kote SR Silicone Conformal Coating 2102 from Techspray is UL recognized for UL746E and provides protection against a variety of environments. |

Tech Specs

Here are some of the technical specifications for UL conformal coatings like Techspray Fine-L Kote SR Silicone Conformal Coating 2102.

|

Type |

Spec |

Definition |

|

Cure |

Coverage (ft.) |

The area that the material will cover |

|

Conductivity |

Thermal Conductivity (W/m°K) |

The ability of a material to conduct or transfer heat |

|

Other Properties |

Shelf Life |

The length of time for which a material may be stored before it becomes unusable |

Resources

Here are some additional resources about UL cure conformal coatings.

- Understanding the UL 746E Standard

- Combustion (Fire) Tests for Plastic Materials

- Do You Need UL Qualification for Your Conformal Coating?

Gluespec is Your Source for Conformal Coatings

Gluespec’s comprehensive and quality-tested database of 35,000 adhesive materials includes the conformal coatings that design engineers need. The materials and manufacturers in our database are not limited to specific suppliers, and data is quality-checked and updated as needed whenever new data sheets or product specifications are released.

If you need deep data on conformal coatings and other materials, you’ll find what you’re looking for in our proprietary adhesives database. Along with technical data and key specifications, you’ll find best practices and comparable materials. Design engineers can also view test method information on dozens of material properties and data points.

Finally, Gluespec’s Advanced Search provides the tools you need to conduct deep filtering among all material properties. The result is a customized grid that contains materials and data points that are specific to your project. Save custom grids for quick access and share them, along with this Conformal Coatings Guide, with your colleagues.